Onggi

'옹기'(Onggi)

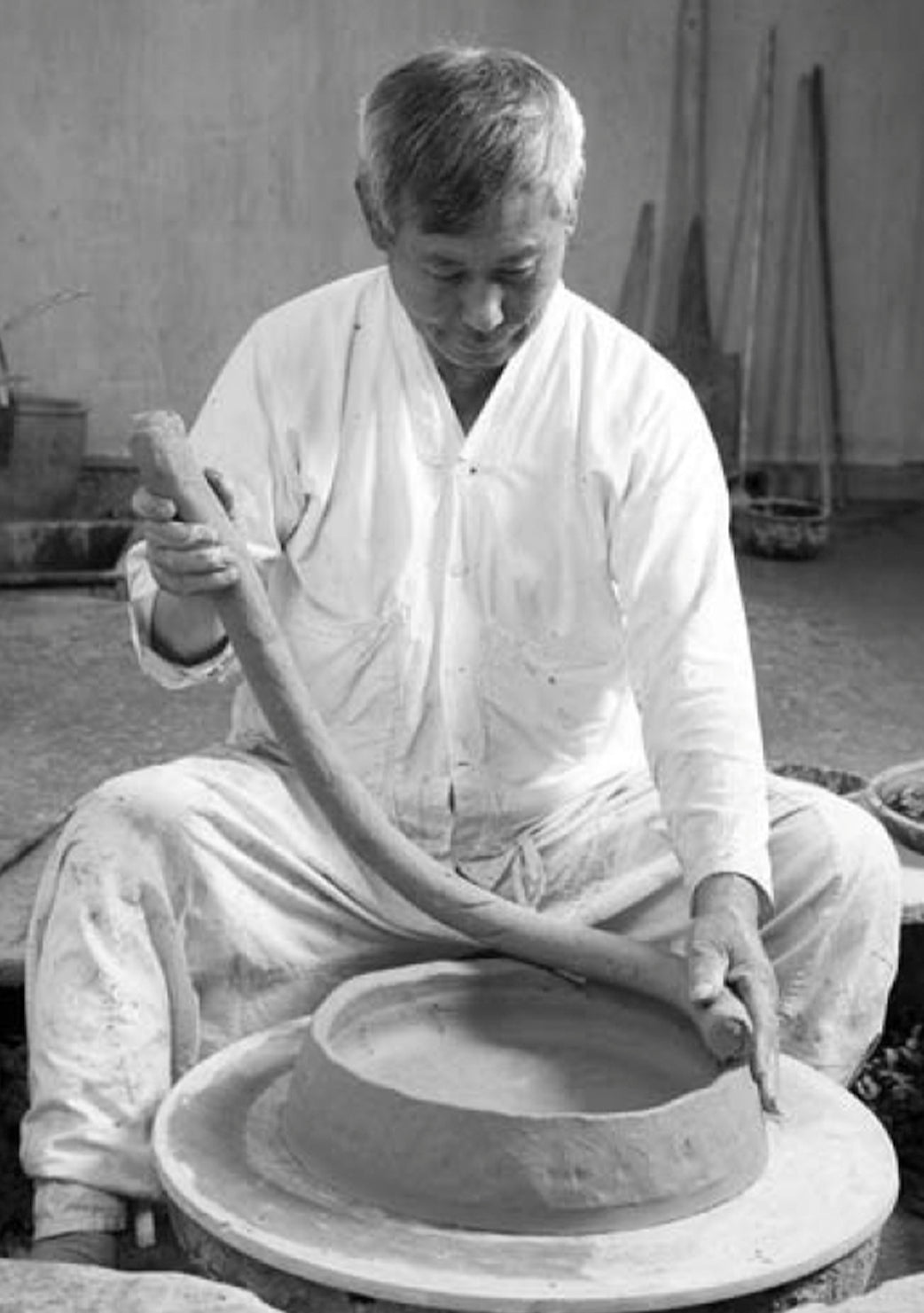

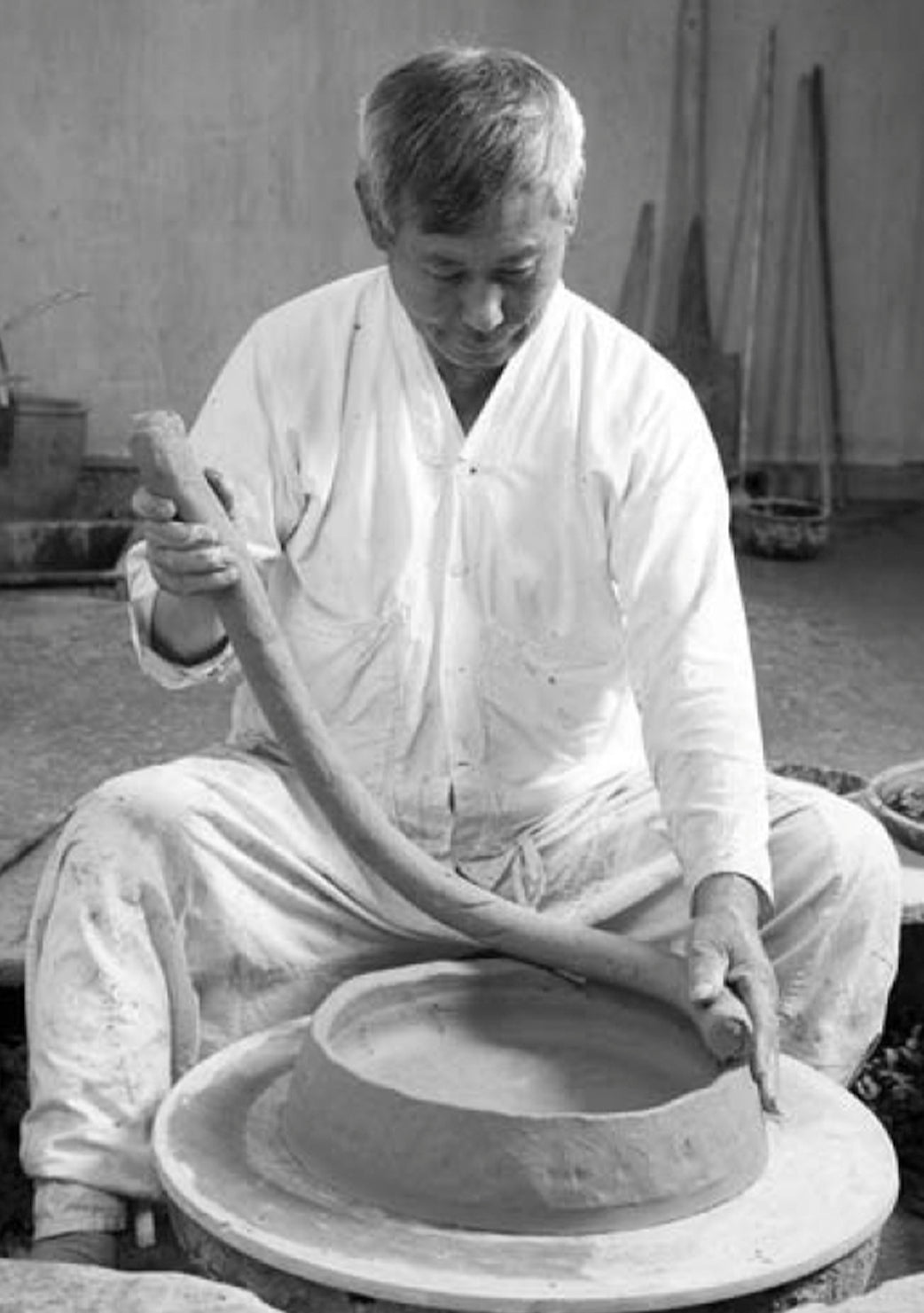

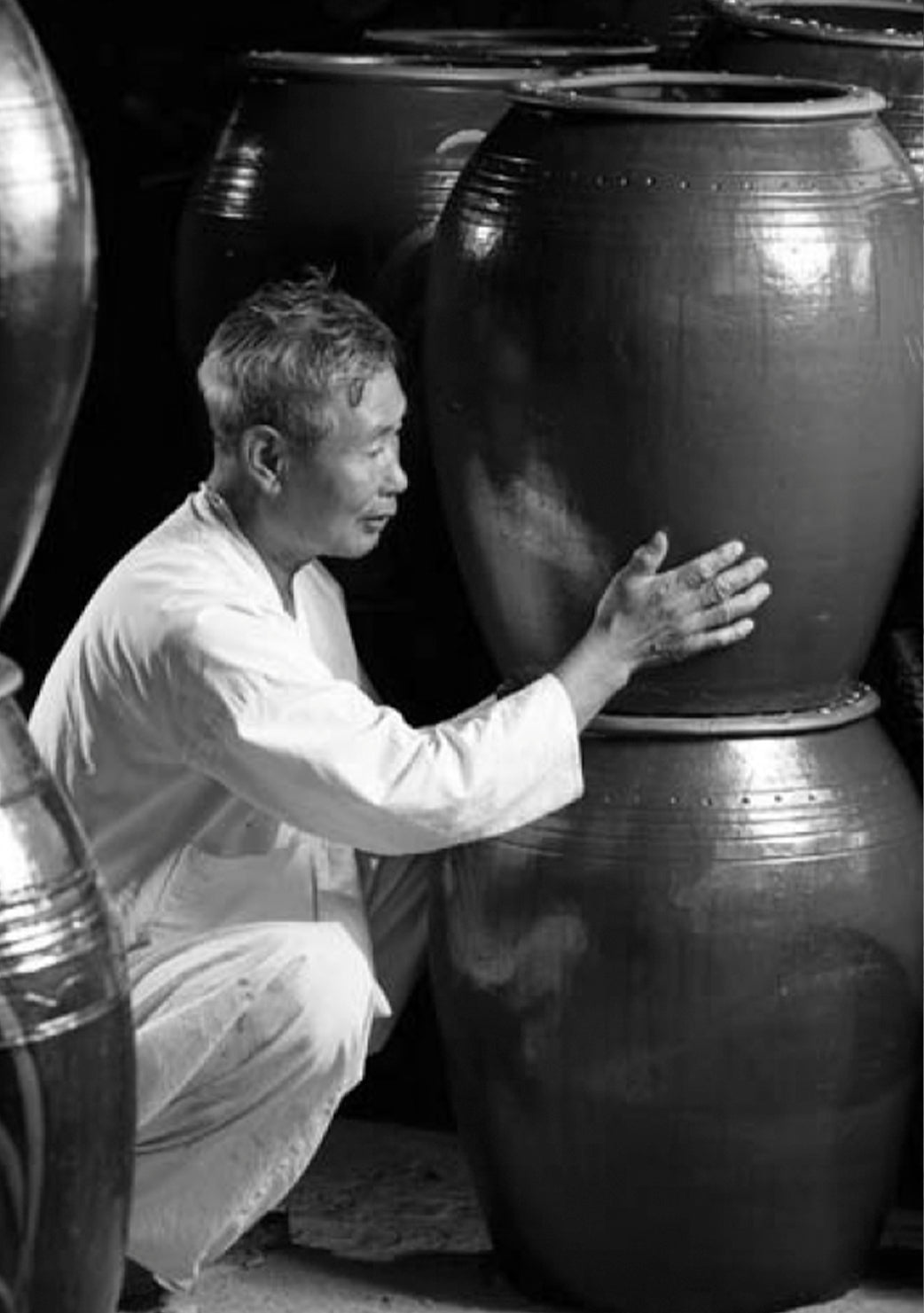

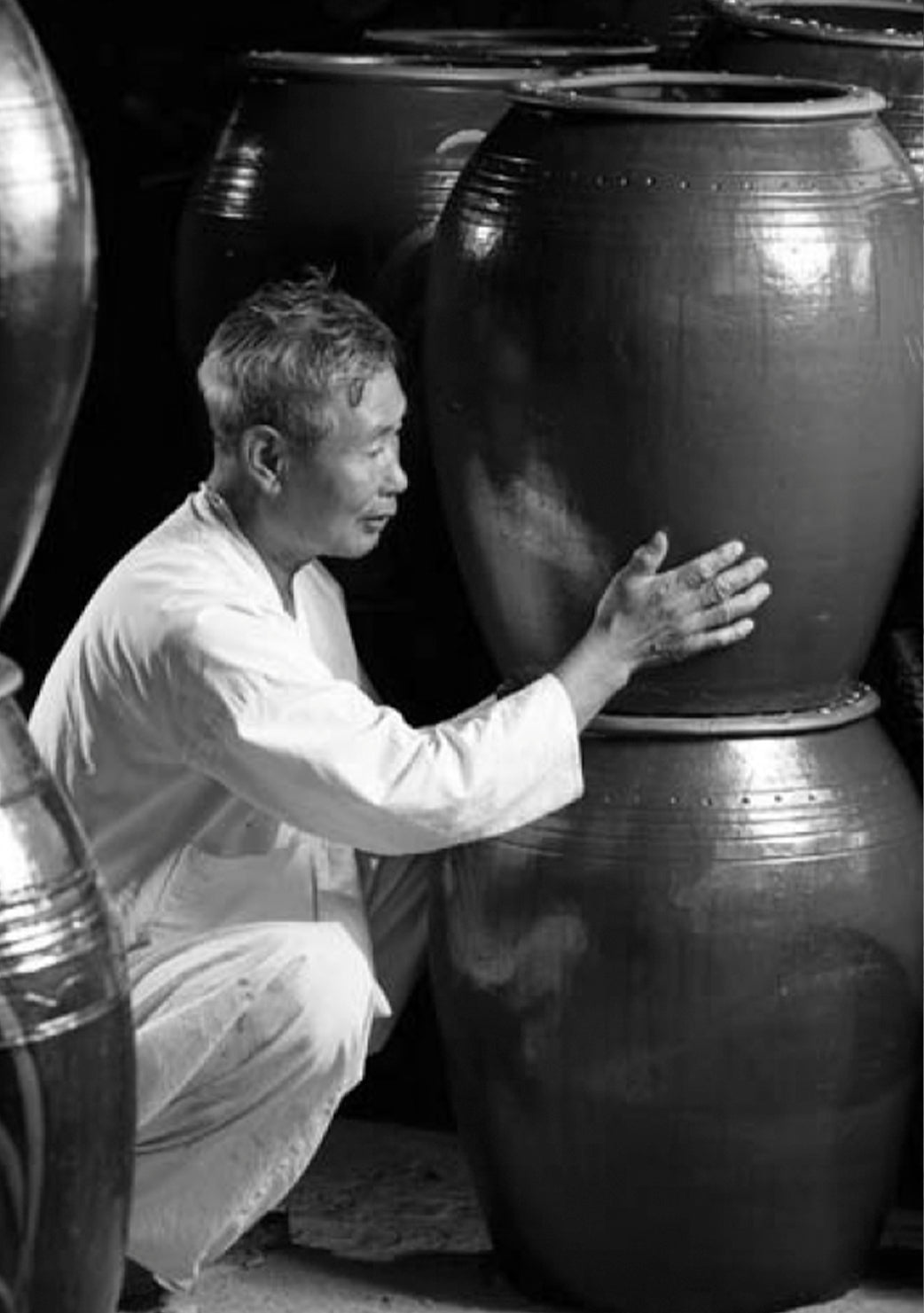

옹기 (Onggi) is a traditional earthenware vessel in Korea that has been used for

thousands of years as part of the nation's household. Onggi vessels are used in

many different ways from storing fermented foods – famously known for Kimchi - to use as kitchenware, bowls and

pots. Because of the unique way it is made – onggi has become a very coveted item in Korean daily life and a

symbol of country's culture.

The ceramics glazing plays a key role in providing a waterproof surface and preventing leaks. A large number of sand particles are added to the body of the clay – these become passages allowing air to move freely through pottery. Onggi is usually fired for about 2-3 days – with the temperature gradually increased up to 1200 celsius degrees. Once onggi is fired the crystal water contained in the wall of the pottery vessel is released making the vessel porous, which allows contents to be stored inside with a longer lifetime. For this reason – onggi was mostly used to ferment food, such as soy sauce, gochujang (chilli pepper paste) and seafood pickles.

Onggi is a natural pottery, it possesses the simplicity of nature but is made with thousand years of experience and wisdom accumulated by the artisans producing it today. Since plastic and metal have been introduced, everyday usage of onggi pottery in Korea has been greatly decreased. Today, however, more people are realising the value of this natural breathing pottery, and are slowly moving away from what is just easily accessible – to something long-lasting and beautiful to look at.

The ceramics glazing plays a key role in providing a waterproof surface and preventing leaks. A large number of sand particles are added to the body of the clay – these become passages allowing air to move freely through pottery. Onggi is usually fired for about 2-3 days – with the temperature gradually increased up to 1200 celsius degrees. Once onggi is fired the crystal water contained in the wall of the pottery vessel is released making the vessel porous, which allows contents to be stored inside with a longer lifetime. For this reason – onggi was mostly used to ferment food, such as soy sauce, gochujang (chilli pepper paste) and seafood pickles.

Onggi is a natural pottery, it possesses the simplicity of nature but is made with thousand years of experience and wisdom accumulated by the artisans producing it today. Since plastic and metal have been introduced, everyday usage of onggi pottery in Korea has been greatly decreased. Today, however, more people are realising the value of this natural breathing pottery, and are slowly moving away from what is just easily accessible – to something long-lasting and beautiful to look at.

© Images provided by

– Cultural Heritage Administration