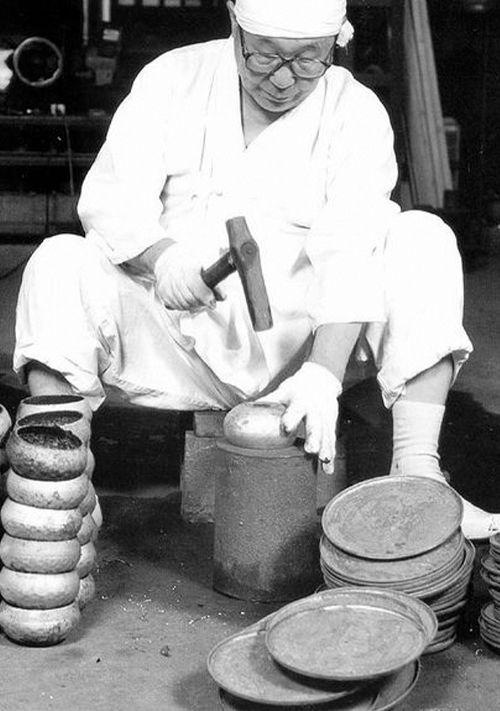

For multiple decades Korea’s Jong Duk Lee has been pursuing

perfection in the ancient craft of

, which is a unique form of metal

work.

comes from the Napcheoung region, a northern part of Korea, where

it was originally used to make bell instruments and also tableware and crockery. Lee has dedicated much of his

life to applying the

technique to traditional instrument and object

making, earning an intangible heritage qualification in Korea. He also encourages others to pick up the

remarkable craft through education of younger artisans,

but today 80% of all the

Based in Tokyo, Ryutaro Yoshida has similarly pursued a career dedicated to craft

in Japan as the co-founder of

Time & Style - a

respected design and furniture brand. It produces pieces for famous architects such as Kengo Kuma and sells

its designs through various retailers across the world. For Yoshida, Time & Style is defined by its close

relationship to the craft

culture of Japan and he enjoys working alongside artisans across the nation to form products that honour the

past but are also appealing to a contemporary audience.

With this in mind,

Yoshida was interested in

speaking with Lee about bangjja, a craft he’s curious to learn more about.

It’s also a craft form that could die out – something that Yoshida’s work in Japan aims to prevent for its

craftspeople. Younger

generations have not been able to move bangjja forward and the Korean

government is not giving the craft enough support. But there is immense importance in bangjja - with its

incredible history and the meticulous making process behind it, it forms some of Korea’s most beautifully

made products, as Yoshida and Lee discuss.

1.

1. 2.

2. 3.

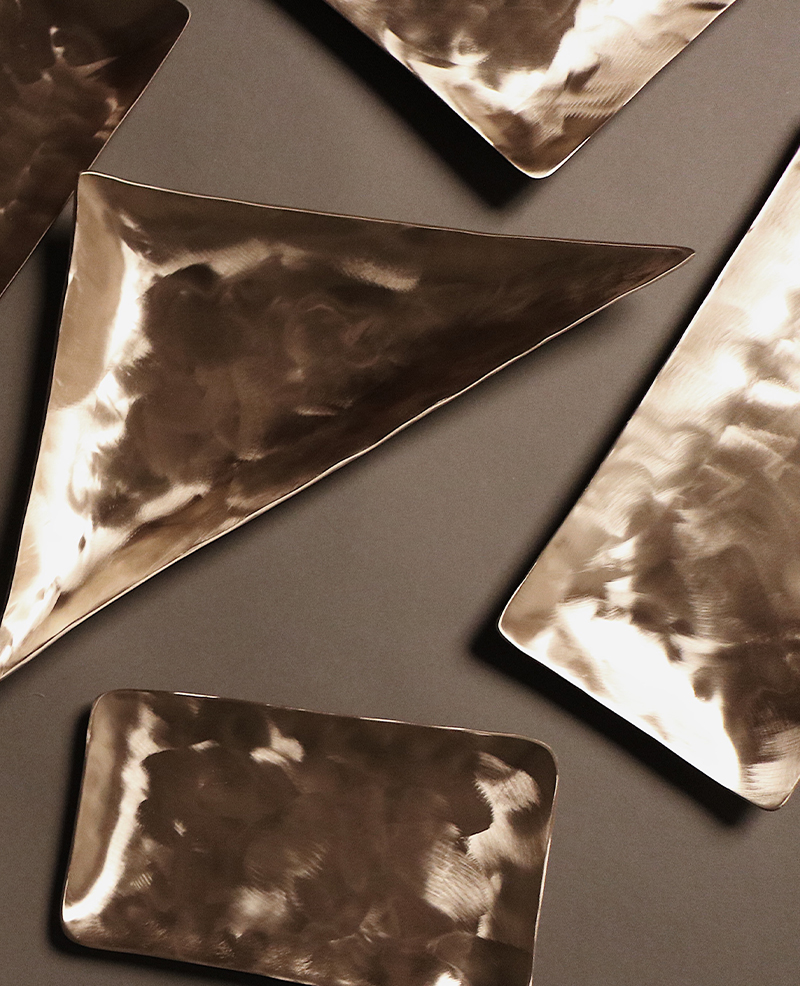

3. 1. Hand-forged plates in different forms

1. Hand-forged plates in different forms 2. Traditional Korean spoon and chopstick sets

2. Traditional Korean spoon and chopstick sets 3. Detail of 항아리 (hangari)—a small jar with Jong Duk

Lee's signature

3. Detail of 항아리 (hangari)—a small jar with Jong Duk

Lee's signature

Jong Duk Lee

Jong Duk Lee Ryutaro Yoshida

Ryutaro Yoshida  4. 종

4. 종

5. 항아리

5. 항아리